pewag

strong is not enough

pewag has hundreds of years of experience in the manufacturing of chains and their components. Since the first documented reference of its forging plant in Brueckl 1479, pewag group became one of the leading chain manufacturers worldwide and the oldest manufacturer of chains and their components. Today its success is based on well-engineered state-of-the-art quality products.

The range of products varies from traction chains for tires (snow chains for passenger cars, trucks and special-purpose vehicles, tire protection chains for mining vehicles) over different industrial chains to products for the do-it-yourself sector (light chains, belts, etc.)

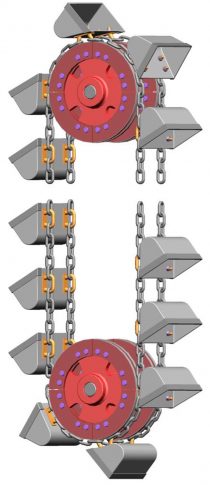

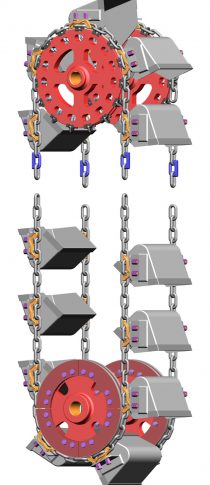

Bracket Elevator Chains and Components

Shackle-system back mounted buckets

SDD-System side mounted buckets

BDD-S side back mounted buckets

BHV Back mounted bucket attachment

Tire protection chains

Traction

• Ice and snow

• Slippery or muddy surfaces

• Steep inclines

• Spinning wheels

• Safety requirements for operator and machine

• Seasonal or continuous use throughout the year

Quarrying

• High diversity of rock, from soft limestone to hard granite, in all sizes

• Load and carry operation

• Seasonal operation

• Premature tire wear and failure

• 1 to 2, maximum 3 shift operation

Slag & Scrap

• Temperatures up to 1,200°C (2,190°F)

• Punctures and tire burning

• Abrasive ground conditions

• Exceptional stress and load

• Limited time for maintenance

• Operation with time limitation

Open Pit Mining

• Large fleet of earthmovers

• Expensive and vulnerable tires

• Huge mining areas

• Millions of tones to be moved

• 24/7 operation

Underground Mining

Characteristics:

• Limited space for chain installation

• Narrow operating space and long driving distances

• Extreme stress and load for the machine, tires and chains

• Difficult equipment and tire maintenance

• Frequent tire failures

• 24/7 operation